Prelonring English

construction and assembly terms:

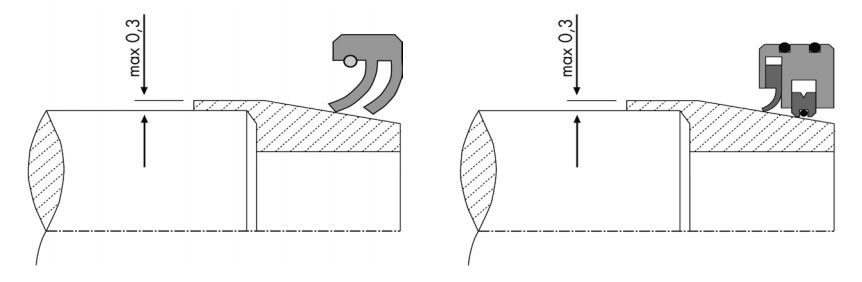

- The sealing space must be axially accessible

- The bore must be closed after assembly to prevent axial movement (out of thesealing space)

- There shall be a little axial clearance of the fitted prelonring because of thermalexpansion (D<200mm: 0,2…0,3mm; D>200mm: 0,5mm)

- Axial pressure on the seal is to be avoided especially for types with a dynamicring/lip (Typ V and V/IV-A)

- Surface finish of the housing Ra=1,8 µm Rt=10 µm

- Surface finish of the shaft Ra=0,2…0,8 µm Rt = 1,0….4,0 µm

- Shaft hardness: 45 HRC … 65 HRC

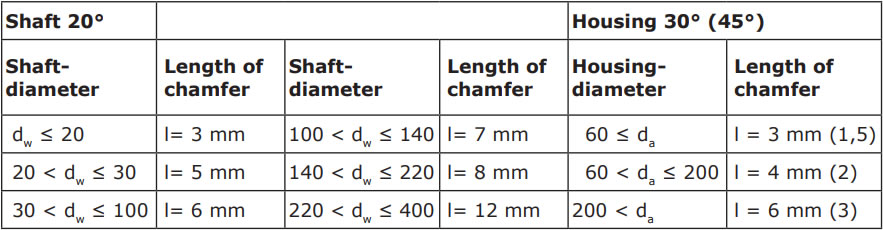

- Tolerances: shaft h11 housing H8